The Power of Vacuum Technology: Applications and Advancements

Vacuum technology encompasses all procedures and measurements conducted in environments with lower-than-normal atmospheric pressure. These processes are typically performed in a vacuum for several reasons:

- To eliminate atmospheric components that might cause chemical or physical reactions during the process, such as vacuum melting of reactive metals like titanium.

- To disrupt equilibrium conditions present at normal room settings, including the extraction of trapped or dissolved gas or volatile liquid from materials (e.g., oil degassing, freeze-drying) or the desorption of gas from surfaces (e.g., cleaning microwave tubes and linear accelerators during manufacturing).

- To increase the distance particles must travel before colliding, allowing them to move without collision between source and target. This is useful in applications such as vacuum coating, particle accelerators, and television picture tubes.

- To decrease the frequency of molecular impacts, thus reducing the likelihood of contamination on surfaces prepared in a vacuum, which is beneficial for clean-surface studies.

Each vacuum process has a maximum allowable pressure, determined by factors such as the number of molecules per unit volume, the mean free path, or the time required to form a monolayer.

At standard temperature and pressure, one cubic foot of air contains about 7 × 10^23 molecules moving randomly at speeds around 1,000 miles per hour. The resulting force on walls equals 14.7 pounds per square inch. Atmospheric pressure was traditionally expressed in millimeters of mercury (mm Hg), with one standard atmosphere equaling 760 mm Hg. The term “torr” was introduced to reconcile these units, where 1 torr = 1 mm Hg. In 1971, the SI unit pascal (N/m^2) replaced the torr, with one pascal equaling 7.5 × 10^-3 torr.

Vacuum technology found its first significant industrial application around 1900 in electric light bulb production. Subsequently, other vacuum-dependent devices emerged, such as electron tubes. It was discovered that certain processes yielded superior results or achieved otherwise impossible outcomes when performed in a vacuum. Examples include improving lens light transmission, preparing blood plasma, and producing reactive metals like titanium. The 1950s nuclear energy boom accelerated vacuum equipment development on a large scale. New applications for vacuum processes continued to emerge, including space simulation and microelectronics.

Various devices have been created to generate, maintain, and measure vacuums, with several significant types described in subsequent sections.

The Evolution of Vacuum Technology

The journey of vacuum technology began in the 17th century with pioneers like Evangelista Torricelli, who created the first sustained vacuum. Robert Boyle’s experiments led to Boyle’s Law, while Amedeo Avogadro’s work established fundamental principles of gas behavior. These early discoveries laid the groundwork for modern vacuum science.

Applications of Vacuum Technology

1. Industrial Manufacturing

Vacuum technology plays a crucial role in various industrial processes:

- Mechanical handling using suction pads

- Vacuum packaging and forming

- Degassing of oils and materials

- Steel stream degassing

- Vacuum distillation

2. Electronics and Semiconductor Industry

- Production of integrated circuits

- Manufacturing of electronic components

- Creation of high-performance displays

3. Metallurgy

- Vacuum melting and casting

- Sintering and heat treatment

- Brazing and welding in controlled environments

4. Chemical and Pharmaceutical Industries

- Freeze-drying of pharmaceuticals and food products

- Vacuum distillation for chemical purification

- Production and storage of vaccines and antibiotics

5. Optical Coatings

- Deposition of thin-film coatings on lenses and mirrors

- Anti-reflection coatings for eyeglasses and camera lenses

6. Aerospace and Space Simulation

- Testing of spacecraft components in vacuum chambers

- Simulation of space environments for research

7. Scientific Research

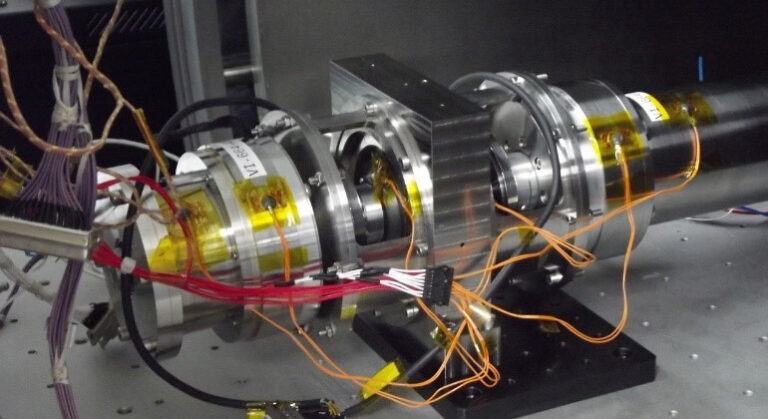

- Particle accelerators and high-energy physics experiments

- Electron microscopy

- Mass spectrometry

Also Read Other Article :-

Vacuum Pumping Systems :-

To achieve and maintain vacuums, various pumping systems are employed:

1. Mechanical Pumps

- Oil-sealed rotary pumps

- Mechanical boosters

2. Diffusion Pumps

- High-speed pumping for industrial applications

3. Turbomolecular Pumps

- Clean, high-vacuum pumping for sensitive applications

4. Cryopumps

- Ultra-high vacuum capabilities

- Used in semiconductor manufacturing and research

5. Ion Pumps

- For ultra-high vacuum applications

- Hydrocarbon-free pumping

Advancements in Vacuum Technology

Recent advancements in vacuum technology have led to:

- Improved energy efficiency in vacuum systems

- Development of “dry” pumping technologies

- Integration of smart controls and IoT capabilities

- Enhanced materials for vacuum chambers and components

The Future of Vacuum Technology :-

As industries continue to evolve, the applications of vacuum technology are expanding. Emerging fields such as quantum computing, nanotechnology, and advanced materials science heavily rely on precise vacuum environments. The ongoing research in fusion energy and particle physics also pushes the boundaries of vacuum technology, driving innovations in ultra-high vacuum systems.

Conclusion :-

Vacuum technology remains an indispensable tool across numerous scientific and industrial domains. Its applications continue to grow, enabling new discoveries and enhancing manufacturing processes. As we look to the future, the ongoing advancements in vacuum technology promise to unlock even more possibilities, driving progress in fields ranging from microelectronics to space exploration. The vacuum, once considered empty space, has truly become a realm of infinite potential.